Introduction

Sterile processing technicians are critical behind the scenes in enabling safe surgeries and medical procedures. Properly cleaning, sterilizing, and preparing medical instruments in hospital central supply units ensures doctors have sterile tools and patients don’t face infection risks from contaminated equipment. This makes understanding sterile processing fundamentals and gaining certified training as a technician an appealing career path.

What is a Sterile Processing Technician?

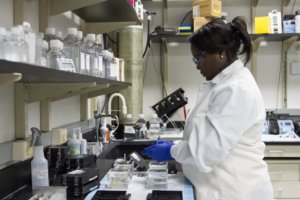

Sterile processing technician training specializes in decontaminating used medical devices and surgical tool sets to render them sterile again for the following procedures. They are central supply experts in busy hospitals, clinics, or dental office decontamination units preparing, cleaning, disinfecting, packaging, cycling through sterilizers, safely storing, and managing critical metal and fiber optic instrument inventories. Precision and efficiency matter significantly preventing backlogs during surges. Sterile processing tech roles focus solely on equipment remediation workflows apart from broader environmental services sanitization.

Why is Sterile Processing Technician Training Important?

With intricate device exposure to bodily fluids during complex surgeries or invasive diagnosis, strict sterile standards minimize infection transmission threats. Technicians uphold these stringent benchmarks consistently behind the scenes through systematic handling, cleaning, and sterilization protocols that destroy contaminants. Formal training equips technicians with specialized knowledge unique from general environmental disinfection covering medical equipment specificity, sterilization machines operation, sterile protocol enforcement, and more. Certification demonstrates competency in tackling contamination thoroughly. Facilities then remain infection-free, trusting protocols that are executed reliably.

Understand the principles of the aseptic technique:

Proper aseptic principles underpin all sterile processing workflows, ensuring no new contaminant is introduced. Techs maintain these stringently by wearing designated scrubs, sterile gloves/gowns when handling sterilized items, and working in restricted-access decontamination rooms.

Perform cleaning and decontamination:

Meticulous manual scrubbing, ultrasonic cleaning, and germicidal disinfectant exposure prepare soiled implements for sterilization. Techs assess and document damages needing repair.

Inspect instruments for damage:

Visual inspections check for wear, tear, or pitting while testing functions catch flaws that may impede performance before reissuing. Damaged tools are removed from circulation.

Assemble instrument sets:

Specialized procedural instrument sets group required tools per surgery type so complete kits consistently stand ready for surgical teams.

Package instruments for sterilization:

Packaging supports sterilization while preserving utility post-cycle during transport and storage. Medical-grade wraps, rigid containers, and peel packs maintain efficacy.

Operate sterilization equipment:

Industrial autoclaves, hydrogen peroxide/ozone/nitrogen dioxide unit-dose systems, and ethylene oxide gas sterilizers activate under precise time/pressure/gas concentrations technicians calibrate to guarantee microbe eradication.

Maintain sterile storage:

Processed sets are warehoused securely to prevent handling damage before surgeons need them, using temperature/humidity control, organization protocols, and germicidal lamps, maintaining integrity over durations.

Maintain accurate records:

Full traceability back to patients ensures containment if recall indications arise. Extensive documentation provides accountability that all technicians handling sets perform Central Service protocols properly.

What are the Benefits of Sterile Processing Technician Training?

Given the integral hospital and clinical infrastructure functions sterile processing provides, formal training unlocks excellent career opportunities, including:

Career Opportunities:

Technician shortages signal strong hiring demand at healthcare facilities, third-party reprocessing centers, and dental/doctor offices offering work/life balance, flexible shift options, and stimulating hospital environments.

Job Security:

Healthcare fields expand reliably despite economic fluctuations. Certified techs remain in demand, handling essential tasks as facility and procedure volumes grow amidst aging populations and technological advances.

Competitive Salaries:

Payscale reports that the average national salary for sterile processing technicians entering the field is approaching $45,000, increasing with certifications, experience, and management roles ($60K+).

Making a Difference:

Although behind the scenes, technicians enable doctors to save lives daily, ensuring sterile instruments are readily available for urgent surgeries and medical interventions when minutes matter most. This critical support role fuels caregiver dedication and job satisfaction while upholding community health.

What are the Typical Requirements for Sterile Processing Technician Training?

Technical expertise aside, specific foundational attributes help candidates excel in managing the responsibilities of this quality-centric medical support function:

High School Diploma or GED:

Further medical education builds on this academic foundation, covering health sciences systematically.

Basic Computer Skills:

Hospital inventory systems necessitate some technology proficiency tracking instrument data for recall readiness and productivity statistics up to healthcare administration databases.

Strong Attention to Detail:

Strict sterile protocol adherence under intense volume pressure requires diligence, ensuring precision repeatability. No minor oversight goes unnoticed if contamination slips through.

Manual Dexterity:

Effectively operating sterilization machinery, handling fragile optics, and manipulating tiny implements need adept motor skills and dexterity cultivated through training repetition.

Teamwork Skills:

Close collaboration with surgical staff and ancillary health providers interdependently across workflows mandates service-focused flexibility and communication supporting well-coordinated sterile supply continuity hospital-wide.

Certification:

The industry-standard Certified Registered Central Service Technician (CRCST) credential offered via the International Association of Healthcare Central Service Materiel Management (IAHCSMM) signals certification to meet industry sterile processing standards responsibly. Many states encourage CRCST status.

Additional Considerations

Beyond foundational abilities and applied skills cultivated in training programs, several other considerations influence trajectories entering sterile processing technician careers:

Salary:

Entry-level sterile processing technicians initially average approximately $14 hourly, increasing to $17+ for CRCST-certified techs and $19+ for specialty experience like inventory control oversight per PayScale with higher supervisory incomes.

Work Environment:

Central sterile supply rooms bustle under intense pressure, enabling urgent surgeries so temperament suits fast-paced environments and standing for entire shifts. Shift coverage also needs man flexible scheduling.

What are the Different Sterile Processing Technician Training Options?

Prospective technicians gain core competencies through several education pathways before passing the CRCST exam:

Certificate Programs:

Many community colleges and vocational schools offer nine-month to 1-year certificates covering decontamination, sterilization, anatomy, procedures, and protocols didactically and via hospital practicums.

Associate’s Degrees:

Some candidates springboard certificates into two-year Biomedical Tech or Surgical technology-focused associate degrees, conferring additional knowledge supporting patient-centered equipment services in healthcare.

On-the-Job Training:

Technicians alternatively certify that they have gained one year of full-time experience under a preceptor’s guidance in facilities. This teaches principles actively but temporarily forgoes wage growth without the CRCST until earned through the challenge exam later.

Conclusion

Given sizable sterile processing technician talent shortages nationwide, hospitals and clinics scramble to recruit candidates to handle equipment remediation demands for constant surgeries. This promising career delivers excellent job security, competitive incomes, and tangible impacts, enabling critical medical interventions through diligent behind-the-scenes equipment decontamination protocols. Formal training like condensed certificate programs imparts essential proficiencies in instrumentation, sterilization, and infection control that hospitals depend on. Once certified as CRCSTs, validating core competencies critical for patient safety and procedural availability, skilled technicians will find rewarding work that sustains day-to-day health services reliably.